ATEX - 5AT/7AT

High Quality Products

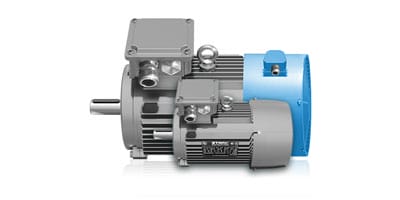

Končar 5AT/7AT Serie – ATEX AC Motors

Explosion-proof and robust. Končar ATEX AC motors are distinguished by their robust design, high IP degree and corrosion-resistant protection. ATEX certification makes these motors explosion proof and therefore suitable for applications in mining, chemical industry, refineries, drilling rigs, fuel pumps and waste management.

Due to their reliability and low maintenance requirements, they contribute to a higher availability of machines and systems.

ATEX AC Motors: features & benefits

ATEX

IE3

IP66

Class F insulation

IEC standard

Versatile options

Technical specifications & more info

Technical specifications

| Motor | 3-phase IEC AC-motor |

| Power range (kW) | 0,18 - 200 |

| Poles (#) | 2, 4, 6 |

| Input speed (rpm) | 3.000, 1.500, 1.000 |

| Voltage/frequency | 230 / 400V - 50Hz; 400/690V - 50 Hz |

| Efficiency class | IE3 (≥0,75kW - 2 / 4 / 6 poles) |

| Protection class | Standard IP55, max. IP66 |

| Motor protection | Optional |

| Isolation class | F |

| Material | Aluminium Cast iron |

| Certificates | CE, UL/CSA, ATEX |

Variations

| IEC Motor size | IEC71 - 315 |

| Motor contruction type | B3, B5, B14A/B, B34 & B35 |

| Output shaft diameter (mm) | 11 - 28 |

| Coating / color | According to ISO 12944 RAL7030 |

Optional features

MIG encoder

Special voltage/frequency

PTC thermistor

Two shaft free ends (on DE and on NDE)

Isolation class H

Special flanges and shaft ends

Flange mounting motors with flange and shaft extension according to NEMA

Terminal box on right or left side

Other colours/coatings

Fan cover with protection from rainfall and textile fibre

non-ventilated (IC410)

Winding for tropical environment

Winding heaters

Condensation drain holes

Roller bearings

Regreasing facility

Marine design

Forced ventilation (cooling type IC416)

Brake

Inquire availability

Repair & Maintenance

Is a current component or drive system in need of maintenance or repair? BEGE has extensive knowledge of a wide variety of drives and systems. We guarantee a rapid resumption of operational procedures.

Your Reliable Partner in Drive Solutions

We make life easier for industrial enterprises by creating, optimizing and maintaining high-quality drives.