Case study

Custom solution for replacement of a discontinued electric motor

Custom solution for replacement of a discontinued electric motor

BEGE supplies specialized custom drive solutions. We support machine builders with our custom drives to help prevent unscheduled downtime. Our distributor and trusted partner Interbridge put us in touch with a US company that needed replacement electric motors for all their factories.

Background & Assignment

Years ago, the company’s former supplier stopped producing the special motors our customer uses in its factories.

As replacement motors were no longer available, the customer had each defective motor repaired and completely rewound by a local shop. This solution proved to be too costly and time-consuming in the long run, so they were looking for an alternative. It was important that the new supplier could deliver these motors and at the same time offer continuity.

The assignment for BEGE was to supply a replacement electric motor so that the customer’s factories could continue running optimally and without unscheduled downtime.

“BEGE has helped us incredibly well. With the limited information we had, BEGE’s engineers actually developed this specific motor from scratch.”

Approach

Unfortunately, the customer did not have any datasheets or motor drawings and could only show a poorly legible sketch, so we decided to send a defective sample to our head office in the Netherlands.

Our engineers examined and measured the motor and developed an initial concept based on all the dimensions. It turned out that the motor did not have standard NEMA or IEC dimensions.

Working method

- Recover data and dimensions

- Examine a defective sample

- Define specifications

- Develop initial concept

- Redevelop and redesign the motor based on the specifications

Result

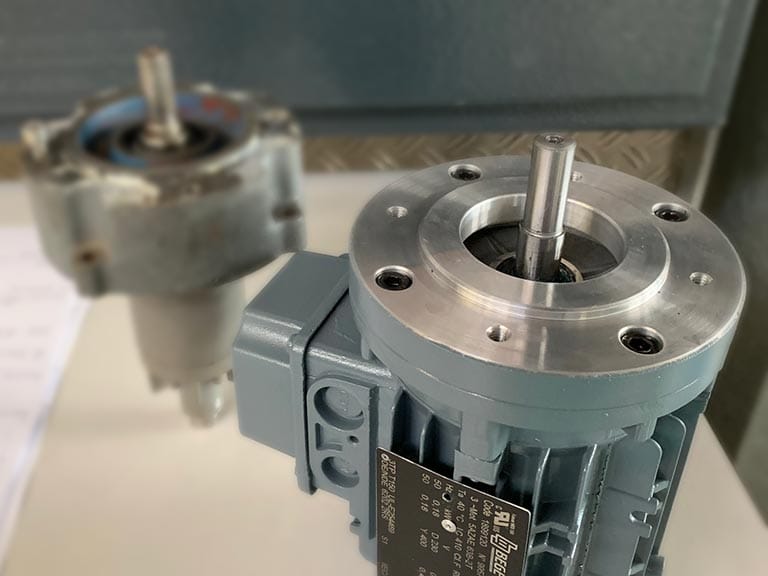

As both the shaft and the flange did not have standard dimensions, and the shaft also had a special flattened keyway, our engineers completely redeveloped the motor based on all the specifications.

To make life easier for our customers, we supply motors with a screened cable connected to star 400V with an EMC gland. This makes it easy to exchange any motor one-to-one. The motors are also available in a TENV version and with a special low-profile terminal box cover, enabling installation in tight spaces.

As the new motors are supplied in IE3 and the customer has more than 100 motors, the switch will result in significant energy and cost savings.

Finally, we will maintain a reserved stock for this customer in the Netherlands and the US to enable rapid replacement. Our smart stock system sends an alert so that stock can be replenished on time.

The results in a nutshell:

- An electric motor that is completely identical to the previous motor thanks to custom engineering

- Worry-free thanks to the connected cable and cable gland for fast one-to-one exchange

- IE3 class for energy and cost savings

- TENV and special low-profile terminal box cover for optimal space utilization

- Reserved stock in the Netherlands and the US for rapid replacement

- Smart stock system so BEGE knows when to replenish stock

- Optimal continuity

- Minimal risk of unscheduled downtime

Want to know more about how BEGE can help your business?

Arrange an appointment with our engineers.