Food Safe Stainless Steel Electric Motors

Efficient, hygienic, affordable and durable stainless steel motors achieve high levels of productivity, efficiency and ease of use.

High-Quality, Efficient and Cost-Effective Stainless Steel Electric Motors

As a drive partner to equipment manufacturers in the industry, we understand that in addition to maximizing production and profit, product safety is the main priority. Legislative requirements for food safety are increasingly strict, both in Europe and worldwide.

Wrong Motor = Major Problems

Whether food products come into contact with the drive or not, these are constantly surrounded by machine parts and devices, making total hygiene a necessity. Selecting the wrong electric motor can lead to major problems, unnecessary expenses or even recalls.

Some issues that equipment manufacturers and their customers face: We don’t want paint chips or rust in the product. We’re fed up with the constant need to replace motors or add new coatings in order to meet hygiene requirements. We want longer-lasting motors. The drive operates in a wet environment and must be able to withstand rigorous cleaning. And finally, we wish to avoid bacterial contamination.

Optimal Product Safety

To ensure product safety in the food processing and manufacturing industry, drives should feature motors that are both efficient and impervious to contamination: stainless steel electric motors.

Unlike motors made of aluminium, for example, barely any moisture or dirt will adhere to a stainless steel electric motor. This is partly due to the choice of materials, but also to the design.

Because a stainless steel motor – unlike an aluminium one – doesn’t require a coating, it can handle high pressure washdowns without a problem. After all, rigorous cleaning doesn’t run the risk of product contamination due to the coating coming off.

The design of the motor takes product safety requirements into account; dirt won’t accumulate easily thanks to the smooth housing and lack of cooling ribs. Combining these material and design features decreases the likelihood of hygiene issues, minimizes contamination hazards and ensures a longer life cycle for stainless steel motors compared to aluminium motors.

Stainless steel motors are efficient, hygienic, affordable and durable. They are a cost effective investment, yielding high levels of productivity, efficiency and ease of use.

We’ve listed seven important advantages of stainless steel electric motors:

- Regulatory compliance

- Food safety

- Hygienic design

- Suitability for high pressure washdowns

- Cost effectiveness

- Durability

- Corrosion resistance

Regulatory Compliance

Stainless steel electric motors meet the latest international rules and regulations for food safety. Hygiene standards (HACCP, EHEDG, FDA) require that installations be capable of withstanding high pressure washdowns.

BEGE offers stainless steel motors that exceed these requirements as standard and can withstand extremely rigorous cleaning; up to 100 bar in close proximity (10-15 cm) and up to 80° Celsius.

Food Safety

Hygienic equipment ensures the safety of the food products being manufactured or processed. Thanks to the rounded, elegantly smooth design, dirt cannot adhere to the motor, preventing bacterial growth.

This makes the use of a stainless steel motor a safety measure for product handling and processing.

Cost Effectiveness

Stainless steel motors offer optimal value for money. A stainless steel motor currently costs approx. 20% – 50% more than its aluminium counterpart.

Investment costs for newer stainless steel electric motors aren’t just lower than previously; they offer savings throughout their lifespan thanks to lower maintenance, fewer replacements, fewer malfunctions and less downtime.

Durability

Stainless steel is popular in industrial applications due to its corrosion resistance. Aggressive cleaning agents will not affect stainless steel motors, as the alloy is resistant to rust and exposure to acid or alkaline substances.

Thanks to the lack of paint or chemicals, stainless steel motors are more environmentally friendly. Moreover, the longer lifespan reduces the total cost of ownership.

Efficient, Cost-Effective Stainless Steel Electric Motors

BEGE supports equipment manufacturers by providing food safe stainless steel motors for the agrifood industry.

BEGE High-Quality Stainless Steel Electric Motors

BEGE has designed cost-effective, efficient stainless steel electric motors in compliance with applicable industry standards. These motors are remarkable for their power, efficiency and food safety. They ensure long term quality performance, with minimal risk of bacteria or contamination thanks to a manufacturing process that meets strict international standards for quality and hygiene.

Our stainless steel motors feature a completely smooth, AISI 304/316 stainless steel housing and are IP69K-certified. The design, development and quality assessment of both our standard and custom motors all take place in Sassenheim.

These electric motors differ from other brands in several ways. The following describes their most distinctive features in more detail.

Standard IP69K

Our standard motors are made of IP69K and feature a PTC resistor to detect overheated windings and shut down the motor in time.

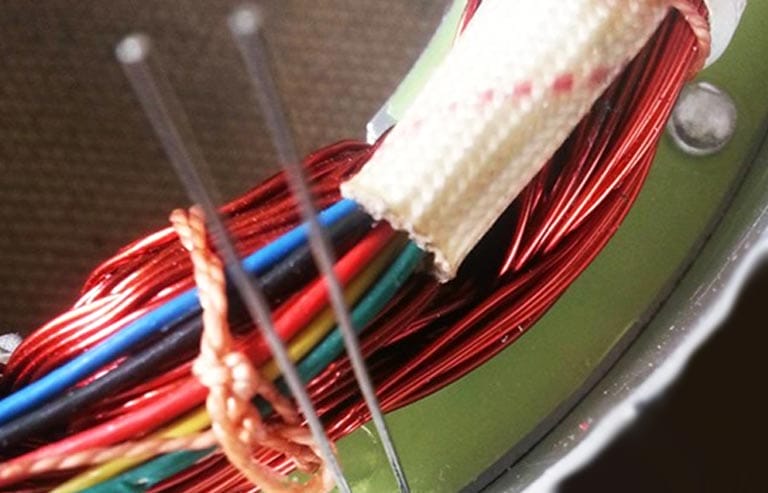

Premium Windings

To ensure optimal performance of our stainless steel motors, we selected high-quality windings that can withstand outside influences such as extreme temperature fluctuations, moisture and overloading.

Additional Features:

- 2 years’ warranty

- UL/CSA certification

- EU engineering

- Engraved motor information

- TENV for 0.18 – 0.75 kW

- TEFC external fan cooling >0.75 kW

- Compliance with HACCP and EHEDG standards

- Food grade quality

- FDA-approved components

- Mounting: B14A, B14B, B5, B3 (other versions on request)

- Suitable for 15 – 75 kHz frequency control

- Pressure relief valve prevents excessive pressure

- High-quality bearings

- Thicker stator walls for lower temperature exterior

Food Safe Stainless Steel Motor Comparison

BEGE offers two ranges of high-quality stainless steel electric motors. These are the KBS Premium stainless steel electric motor and the cost-effective EBS. Either is eminently suitable for applications in the food processing and manufacturing industry. Both ranges offer efficient performance and contribute to a food safe environment. Even so, there are differences. The following describes the variations in more detail.

KBS Premium

Efficiency class

IE3

Power range

0,18 – 1,5kW

Frame size

IEC 63 – 90

Poles (#)

2, 4, 6, 8

Protection class

IP69K

Cooling

TENV

Isolation class

H

Motor protection

Bi-metaal

Material

AISI 316

Applications

Conveyor belts or fans in commercial freezers which are kept at -40°C and regularly defrosted for high pressure washdowns with acid or alkaline cleaning agents.

Convection ovens and bakery equipment that operate under ambient temperatures of >35°C, with an S1 (100%) duty cycle and overloading for brief periods.

Fish processing equipment in remote (offshore) locations where downtime is unacceptable and a long lifespan is mandatory.

EBS Economy

Efficiency class

IE3

Power range

0,18 – 22kW

Frame size

IEC 63 – 132

Poles (#)

2, 4, 6

Protection class

IP69K

Cooling

TENV / TEFC

Isolation class

F

Motor protection

PTC, anti-condensation heater

Material

AISI 304

Applications

Slaughterhouses, dairy plants and meat and fish processing installations where food safety is a priority and the equipment is subject to regular high pressure washdowns.

Pharmaceutical commercial applications with a controlled ambient temperature of -5°C to +25°C, where the motor operates continuously under constant load (S1-100%) and the operating temperature may or may not be reached.

Cost-effective food processing equipment containing stainless steel electric motors in compliance with the rules and regulations, where purchase price is an important consideration and any replacements must be quick and easy.

BGX IE4

Efficiency class

IE4

Power range

0,18 – 3kW

Frame size

IEC 63 – 132

Poles (#)

2, 4, 6

Protection class

IP69K

Cooling

TENV / TEFC

Isolation class

F

Motor protection

PTC, anti-condensation heater

Material

AISI 304

Applications

These ultra-high efficiency motors make a drive fit for the future. They comply with the new legislation that will take effect on 1 July 2023. From this date, the IE4 Super Premium Efficiency level will apply to three-phase motors from 750 W to 200 kW.

They are ideal for use in industries with special hygiene requirements such as the food and pharmaceutical industries.

BGX IE4 Super Premium Efficiency stainless steel motors offer ultimate efficiency and performance with minimal replacement and downtime.

Catalogue available soon

Specialist in Stainless Steel Drive Systems

BEGE isn’t just a supplier and manufacturer of stainless steel electric motors. We employ innovative technology to engineer complete drive systems and custom solutions that meet sector or customer-specific demands. We guarantee that all components will work together seamlessly. The contact with a single partner keeps everything straightforward. See the seven advantages of BEGE’s integrated drive systems.

A stainless steel drive system for the food processing industry often consists of a combination of a KBS, EBS electric motor, GE gear motor, KE helical-bevel gear motor, or a stainless steel drum motor with a MIG flange encoder and a frequency inverter.

BEGE service benefits

- Extensive range of stainless steel electric motors

- Customization options for customer-specific solutions

- Quick delivery thanks to large inventory in Sassenheim

- Reserved inventory

- Quick delivery of spare parts

- On-site repair and service

- EU-engineered for reliable quality

- Support in your own language