Industrial coatings

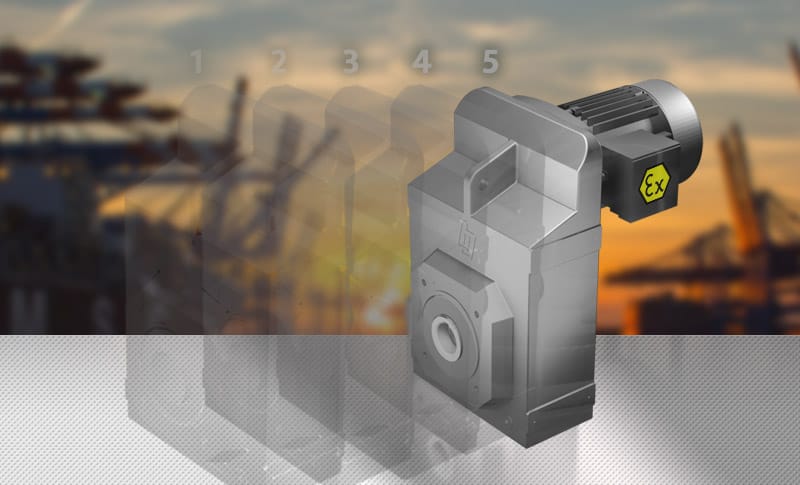

We protect our drives with industrial coatings for longer service life. Hygienic, reliable and resistant.

Industrial coatings for optimally protected drives

BEGE offers drives with a longer service life thanks to professional coatings tailored to specific applications.

Safety and continuity thanks to industrial coatings

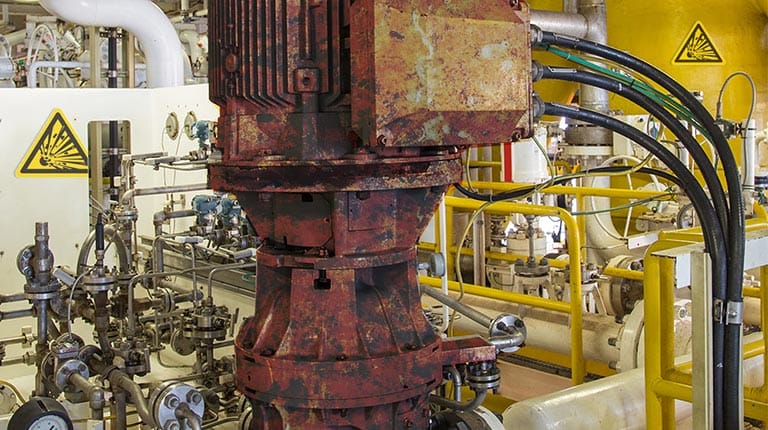

Corrosion and rust are a threat to the life of an aluminum or cast-iron drive unit. A gearbox in the marine sector that is almost constantly exposed to salt and heavy soiling must be resistant to corrosion to avoid the risk of explosion or motor failure.

In food processing machinery, a toxic coating can create a severe health hazard if it unexpectedly flakes off.

To ensure safety and continuity, we supply drives with industrial coatings. This protects our aluminum and cast-iron gear motors, gearboxes and electric motors and makes them more durable. The high-quality coatings offer excellent protection against dirt, bacteria and corrosion. This saves time, money and resources, and it extends the life of the drive.

Benefits of industrial coatings in power drive technology

Food-safe STEEL-IT coating

Machines in the food industry often come into contact with moisture, fats and bacteria. For thorough cleaning, they must be resistant to water and aggressive cleaning agents. By applying a corrosion-resistant coating to an aluminum motor, gearbox or gear motor, we offer an alternative to a more expensive stainless steel version.

We use a two-component acrylic resin paint to give the drive a weather-resistant top coat with excellent surface hardness.

The STEEL-IT coating has been specifically developed for treating materials that come into occasional contact with food, in accordance with HACCP requirements. The manufacturer is the market leader in corrosion-resistant and durable coatings. They are known for their unrivaled stainless steel micro-flakes, and the addition of a 316L stainless steel reinforcing agent makes the paint very durable and corrosion resistant. With a STEEL-IT coating, the surface is effectively 50% high quality stainless steel, which explains the paint’s robust protection.

The coating is suitable for applications where food contact is neither intended nor continuous, such as food processing equipment where no components of the coating migrate into the food and become part of the food. Therefore, STEEL-IT Epoxy coating is USDA-compliant for incidental food contact.

- Suitable for contact with disinfectants in frequent cleaning cycles

- USDA-compliant for incidental food contact

- Fast and reliable cleaning due to its corrosion-resistant and durable properties

- Ideal for applications such as food production, processing, filling and packaging

Corrosion-resistant coating

Machines in the marine and offshore sector are exposed to humidity, wind, cold, heat, salt and chemicals every day. This can lead to corrosion or other forms of wear, adversely affecting production quality, continuity and ease of maintenance.

To prevent drive corrosion, we apply a special C5M coating to our cast-iron gearboxes and electric motors. This protects them against surface rust and oxidation, among other things. The coating we apply to drives in marine and offshore environments is resistant to mineral oil, lubricants, emulsions and solvents. Aggressive environmental conditions do not affect the coated drive components, and the coating makes it easy to remove deposits such as bacteria or microorganisms.

The adhesion, hardness and impact strength are excellent, and chemical resistance is high. The protective coating forms a seal to provide excellent rust protection. The paint is water-based, so it is less harmful to people and the environment than solvent-based coatings.

We adapt the treatment method to the application of the drive unit. We also consider the corrosion categories described in EN ISO 12944-2.

- Suitable for use in an industrial atmosphere

- Suitable for use in environments with aggressive atmospheric conditions

- Suitable for use in environments with high salt load and humidity

- Ideal for marine, offshore and packaging applications

Reliable drives in a corrosion-free and hygienic environment

Longer life thanks to coatings that provide protection against wear, heat, moisture, corrosion and chemicals.

The right coating for the right application

For every application, we have a suitable coating to protect the motor or gearbox.

For each corrosivity class, we offer a specific treatment that varies in terms of the type of paint used and the number of coats, and of course adapted to the surface: rough, smooth, aluminum or cast iron. For example, we prepare a normal drive (C1–C4) with a 20 micron primer, and for stronger coatings we use an epoxy primer. We then apply one or more coats of one- or two-component acrylic resin paint and let the coating cure. For specific marine or offshore applications (C5-M), we add an additional aqua coat, or for the food industry (C2) we use a STEEL-IT coating with stainless steel flakes. The following overview shows the specifications of the various coatings.

ALL INDUSTRIES

Class

C1

Corrosivity

Heated buildings

Protection

IP55-IP67

Price level

€€€€

Food contact

Certification

Dry environment

Wet environment

High-pressure cleaning

Protection duration

++

Chemical cleaning

Saltwater environment

High hygiene requirements

ALL INDUSTRIES

Class

C2 – C5I

Corrosivity

Environments with (high) condensation

Protection

IP55-IP67

Price level

€€€€

Food contact

Incidental

Certification

Dry environment

Wet environment

High-pressure cleaning

Protection duration

+++

Chemical cleaning

Saltwater environment

High hygiene requirements

MARINE

Class

C5-M

Corrosivity

Environments with high condensation and pollution or salt content

Protection

IP55-IP67

Price level

€€€€

Food contact

Certification

Dry environment

Wet environment

High-pressure cleaning

Protection duration

++++

Chemical cleaning

Saltwater environment

High hygiene requirements

FOOD & BEVERAGE

Class

C2 Food

Corrosivity

STEEL-IT coating in combination with aseptic design

Protection

IP55-IP67

Price level

€€€€

Food contact

Certification

FDA / NOTOX

Dry environment

Wet environment

High-pressure cleaning

Protection duration

+++

Chemical cleaning

Saltwater environment

High hygiene requirements

FOOD & BEVERAGE

Class

Stainless steel

Corrosivity

Non-coated drive

Protection

IP69K

Price level

€€€€

Food contact

Direct

Certification

FDA / NOTOX

Dry environment

Wet environment

High-pressure cleaning

Protection duration

++++

Chemical cleaning

Saltwater environment

High hygiene requirements

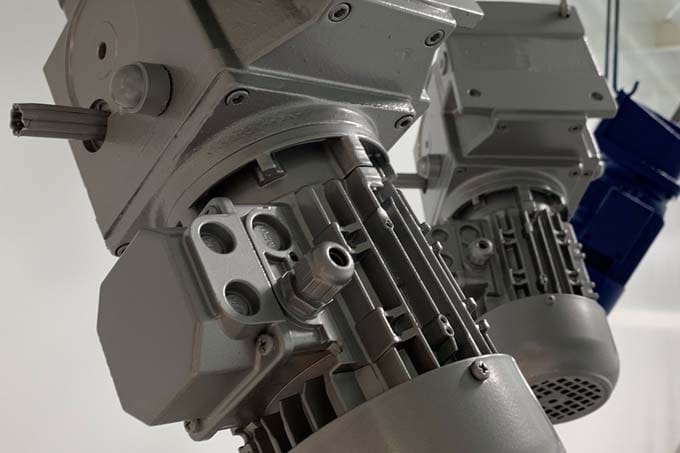

Spraying the entire drive unit

With our 2K water-based paint and STEEL-IT coating we spray the entire drive. Spraying the back shield, the fan cover and the inside of the fan cover gives the drive system even better protection.

This complete approach prevents corrosion on the inside and contributes to the longer life of the drive.

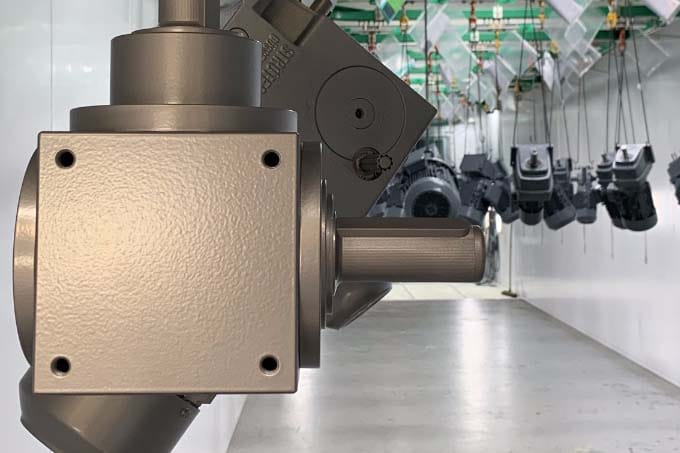

Modern spray booth

BEGE has its own professional spray booth. Thanks to the suspended transport system it is possible to efficiently coat drives of various sizes and weights without the risk of damage.

This allows us to easily spray in series, with a high-quality coating and fast delivery as a result.

High quality drives

BEGE offers high-quality drives with optimal protection for longer life.

Want to find out which coating best protects your drive? We will be happy to assist you with technical support and expert advice.

High-quality stainless steel drives

For enterprises in the food industry that prefer stainless steel despite the advantages of a coated aluminum drive, BEGE has been producing cost-effective and efficient aseptic stainless steel drives for many years. They are ideal for applications subject to extremely stringent international standards for quality and hygiene, such as the agri-food sector.

This product line excels in power, efficiency and food safety and ensures long-term quality. The housing of our stainless steel motors is very smooth so that dirt cannot adhere, and the design does not have any openings, so bacteria or other microorganisms cannot get a toehold.

Read more about our food-safe stainless steel motors or stainless steel drives.

Sign up for BEGE news and updates