Automation for bulk materials

A sturdy and certified integrated drive solution for the processing of bulk materials in a safe and productive work environment.

BEGE: automation partner for the bulk materials industry

BEGE supports machine builders, manufacturers and other players in this sector with optimal automation solutions. Our extensive knowledge of the industry enables us to always deliver a suitable drive or controller.

Co-engineering for drives in the bulk materials sector.

We are one of the few suppliers on the market that works closely with our customers’ professionals. Through co-engineering, we work together to create smart and efficient drive and control solutions for this industry.

It’s not about what we make, but about what we make possible.

Automation for the bulk materials sector

Custom drives for the bulk materials industry

We develop and manufacture custom drives and automation solutions. Together with our customers in the bulk materials sector, we have already implemented many tailored solutions. A number of applications are shown below. Move over an area to read more details.

Filling big bags with dry animal feed

(Animal) food

Filling big bags

Wish: Fill bulk bags in big bag system with dry feed (grains, legumes, soy scrap).

Solution: VFD shaker or vibrator plate for perfect big bag filling. Compacts product and makes transportation easier.

Waste flow conveyor

Recycling & waste disposal

Waste flow conveyor

Wish: Discharge waste from vibratory feed to cyclone separator.

Solution: Conveyor with drive drum and thermal overload protection carries waste to high-speed magnetic rotor.

Mineral and stone handling

Mining & minerals

Mineral and stone handling

Wish: Process minerals or stone in a transfer system using belt, chain or plate conveyors.

Solution: Conveyors with integrated protected drum motors feed the material. Belt alignment, emergency pull and position switches operated easily from central HMI control panel.

Separating material with a wind sifter

Recycling & waste disposal

Operating wind sifter

Wish: Separate different-weight particles (household waste, paper and plastic) using a wind sifter.

Solution: Easily adjustable VFD fan generates crossflow that separates heavy materials from light materials.

Vertical transport of bulk material

(Animal) food

Vertical bulk transport

Wish: Efficiently transport grains or other dry, non-abrasive or pressed materials to great heights.

Solution: VFD vertical conveyors, elevating conveyors or bucket elevators for high silos or factories. VFD system ensures correct speed and throughput.

Sieving and separating rubber granulate

Recycling & waste disposal

Sieving and separating rubber granulate

Wish: Sort rubber tire granulate with a rotary sieve.

Solution: Electrically driven adjustable eccentric weights optimize horizontal amplitude for higher capacity. Sieve separator produces swirling vibratory motion to improve separation based on shape and size.

Frequency regulation for herb supply

(Animal) food

Herb and powder feed

Wish: Correct herb or powder feed for big bags or plastic-sealed cartons.

Solution: Stainless steel dosing screws with VFD. PLC with MIG encoder automatically places package at the right filling point. Speed and filling time can easily be adjusted.

Driving decanting machine

Mining & minerals

Driving decanting machine

Wish: Separate ores (gold, silver, copper) in a decanter with a differential bowl and scroll drive.

Solution: Encoder feedback makes the scroll speed different from the bowl speed, so the separated solids move to the end of the bowl.

Ribbon screw mixer for baby powders

(Animal) food

Mixing baby powders

Wish: Optimal mix accuracy with ribbon screw mixer for baby powders with unimpaired quality.

Solution: Bevel gear motors for high radial loads ensure high and adjustable agitator speed. Forced cooling maintains motor efficiency even at very low speeds.

Dust-free emptying of powder drums

Mining & minerals

Dust-free drum emptying

Wish: Empty mineral powder drums dust-free at a safe distance.

Solution: Drum/container handling system automatically removes lid, then a servo-driven arm grips, turns and empties the drum dust-free with the operator at a safe distance.

ATEX fan motor

Mining & minerals

ATEX fan motor

Wish: Compact, safe dust collection system for industrial applications with suction filter and integrated fan.

Solution: ATEX certified fan motor driven by VFD. Filter/cleaning levels set on HMI screen. Integrated forced cooling maintains motor efficiency even at 5 Hz.

Electronic waste shredding

Recycling & waste disposal

Electronic waste shredding

Wish: Crush electronic/electrical waste, cables and aluminum scrap with a granulator or shredder.

Solution: A mechanical controller operating according to the power consumption of the VFD motor ensures optimal machine loading.

VFD for hammer mills

(Animal) food

VFD for hammer mills

Wish: Grind soft to medium-hard products such as grains and sugars.

Solution: Easily adjustable VFD in hammer mill precisely matches rotor speed to desired result. Select fine or coarse grinding on integrated HMI screen.

Limiting moisture in plastic flake stream

Recycling & waste disposal

Flake stream drying

Wish: After washing, tumble dry a plastic flake stream to reduce moisture.

Solution: Powerful, energy-efficient three-phase motors produce centrifugal force resulting in high friction, driving moisture out of the material.

Correct dosing in extraction process

Mining & minerals

Correct dosing in extraction process

Wish: Constant flow of sand and gravel during extraction from silo with vibrating chute.

Solution: A vibration motor perfectly matched to the application, bulk material and weight ensures correct dosing.

Swipe ->

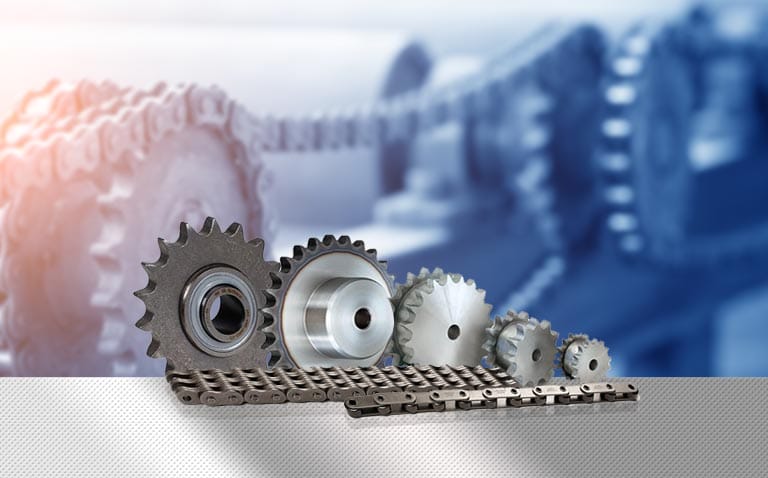

Drive components for the bulk materials industry

Drive solutions for the bulk materials Industry

Our reliable drive systems feature low maintenance, long service life and high efficiency. This makes them highly suited to applications in harsh environments.

Related topics and developments

Attractive products and comparisons for the bulk materials industry.

Want to know how our bulk materials automation solutions can help you? Feel free to contact us.