Comparison of hypoid, helical bevel and worm gear motors

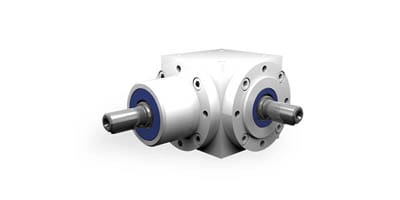

Strong and sturdy right angle gear motors for top performance and optimal axial and radial load capacity.

Comparison of right angle transmissions

For centuries, gears have been used to move things or to change direction or speed. In drive technology, it is often necessary to transmit motion at an angle of 90°, for example to save space or to fit the gear unit on a hollow shaft. In these situations, we use right angle gear motors.

Various types of right angle transmissions are available: helical bevel, worm and hypoid. Every gear motor supplied by BEGE is strong and sturdy, and each has its own specific characteristics, advantages and applications.

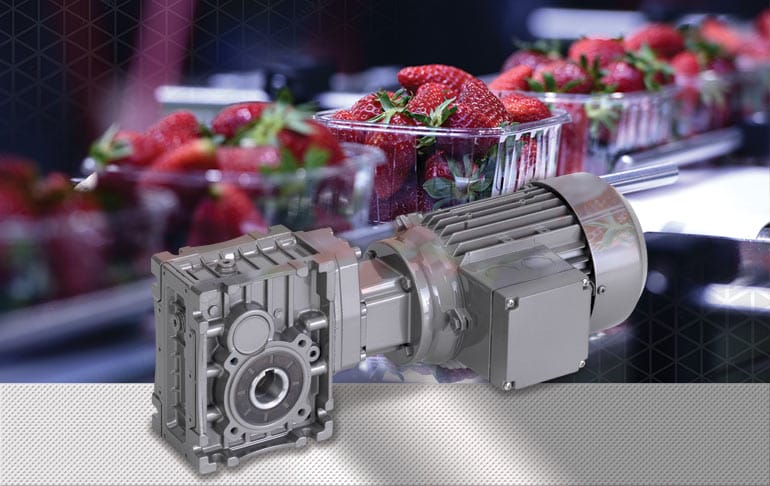

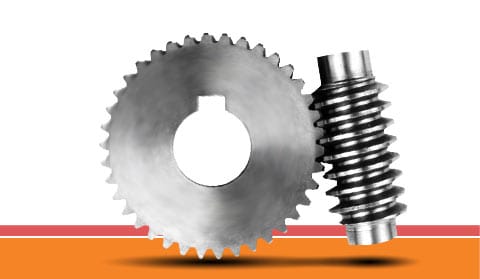

Worm Gear Motors

A worm gear unit consists of a worm and a worm wheel. The worm resembles a screw and meshes with the teeth of the worm wheel. When the worm is driven, the worm wheel turns slowly with high torque.

Self-braking

In the other direction, the combination is self-braking. This occurs if the pitch angle of the worm is smaller than the friction angle, or if the gear ratio is large enough. As a result, a worm gear unit is self-braking when the force direction is reversed. This self-braking capacity often eliminates the need to buy a more expensive brake motor.

Universal solution

Worm gear motors are characterized by high quality, compactness and a universal design. This allows the gear unit to be mounted in various ways in the machine or application. These powerful transmissions are quiet, shock-resistant, and meet today’s high demands in every respect.

Applications

- Food industry

- Conveyors

- Agricultural and horticultural systems

- Marine and offshore

- Systems with self-braking capability

Advantages

- Compact and universal design

- Economical

- Self-braking with certain gear ratios

- Also available in stainless steel or with a stainless steel hollow shaft

- Sturdy and quiet solution

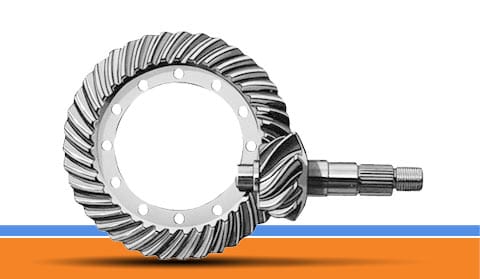

Hypoid Gear Motors

Our energy-efficient alternative to a worm gear transmission, the hypoid gear motor, has special hyperboloidal gears whose center lines are offset instead of intersecting. The advantage of hypoid gears is high gear ratios up to 300:1.

Efficiency

Unlike conventional worm gear transmissions where significant losses occur due to high sliding resistance between the worm and the worm wheel, hypoid gear units have mainly rolling resistance between the gears. This rolling resistance produces virtually no losses and ensures high efficiency. BEGE’s hypoid gear units have Gleason helical teeth and one or two gear stages with helical gearing. All gears are hardened and ground and have hyperboloidal gear geometry.

Energy-efficient alternative

The hypoid gear unit differs from the worm gear unit in terms of energy efficiency, especially with higher gear ratios. The design also features interchangeability with existing conventional worm gear units.

All this makes a hypoid gear motor a highly suitable energy-efficient alternative to a conventional worm gear unit.

Applications

- Food industry

- Large gear ratios in limited space

- Conveyors

- Energy-efficient alternative to worm gear units

- Agricultural and horticultural machinery

Advantages

- High efficiency

- Very high gear ratios

- Directly interchangeable with conventional worm gear units

- Less vibration and low noise level

- Interchangeable flanges, couplings and shafts

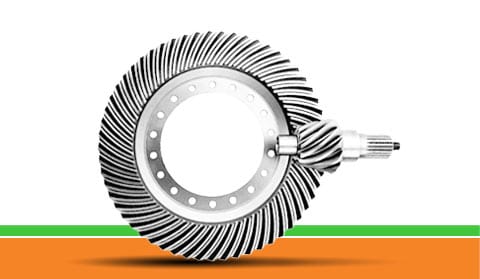

Helical Bevel Gear Motors

Achieving our most efficient right angle solution requires beveled (conical) gears. This type of gear has helical teeth, and the center lines of the gears intersect. We offer two- stage and three-stage helical bevel gear transmissions and always use hardened and ground gears.

Efficiency

Optimal gear geometry and high machining accuracy result in a transmission where the teeth always mesh nicely and the rolling resistance is minimal. This gives helical bevel gear units very high efficiency and makes them ideal for S1-100% use in medium to heavy industry. Our universal right angle helical bevel gear motors offer consistent and optimal reliability under harsh operating conditions.

Long life

The higher the efficiency, the less heat and wear on the gears, bearings and seals. This means that helical bevel gear motors last longer, and longer life means less downtime and lower TCO of the drive.

Applications

- In general mechanical engineering

- Packaging machines and logistics solutions

- Conveyors

- Heavy-duty applications such as marine and offshore

Advantages

- High efficiency and low maintenance

- Suitable for harsh environments and S1-100%

- Various shaft and flange configurations possible thanks to the modular system

- Also available in stainless steel or with a stainless steel hollow shaft

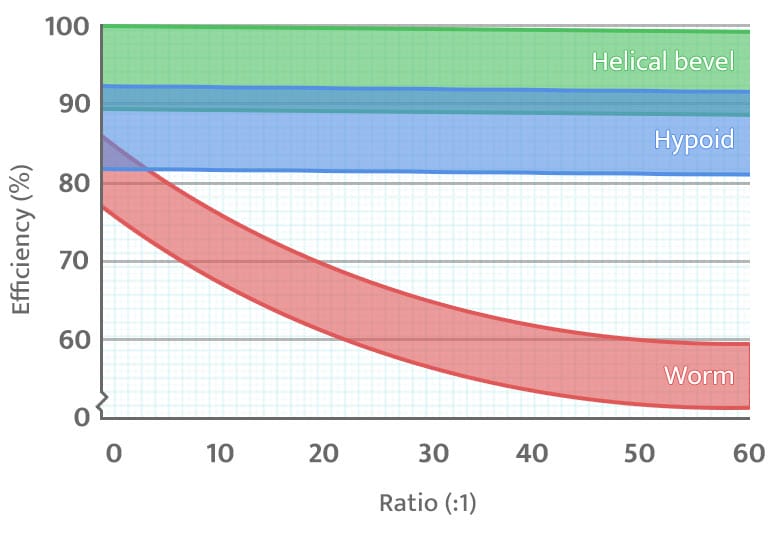

Efficiency versus type of right angle transmission

Of all three transmission types, the worm gear motor has the lowest efficiency. Hypoid gear motors provide higher efficiency, but for the best efficiency you should choose a helical bevel gear motor.

The efficiency of a worm gear unit drops sharply with increasing gear ratio. With a gear ratio of 5 to 10, the efficiency is above 85%. If the ratio rises to 100, the efficiency of the worm gear unit is only 50%. At relatively low speeds, the efficiency of a worm gear drops more than the efficiency of a helical bevel gear or hypoid gear.

Our experience shows that the average efficiency of a hypoid gear unit is 88% with two stages and 83% with three stages. The efficiency of a helical bevel gear unit can be up to 98% due to the exclusively rolling friction.

To optimize energy efficiency, we lubricate the gears in our hypoid and worm gear units with an ISO VG320 synthetic oil based on polyglycols (PG). Our helical bevel gear units are lubricated as standard with an ISO VG320 synthetic oil-based on poly-alphaolefins (PAO).

These oils have the right viscosity, which helps to reduce friction and heat, and are suitable for ambient temperatures from -5°C to +40°C. For specific applications, we have various special lubricants available.

Comparison of hypoid, helical bevel and worm gear motors

We have a suitable gear motor for every right angle transmission task. See the differences at a glance.

Type

Worm gear

Product

RVM and SE series

Min. gear ratio

7.5:1

Max. gear ratio

100:1

Efficiency

50–85%

Friction

Sliding

Heat generation

+++

Lifetime

+++

Noise level

+++

Price

€€€€

Type

Hypoid gear

Product

BPM series

Min. gear ratio

7.5:1

Max. gear ratio

300:1

Efficiency

83–88%

Friction

Mainly rolling

Heat generation

+++

Lifetime

+++

Noise level

+++

Price

€€€€

Type

Helical bevel gear

Product

K and KE series

Min. gear ratio

3.73:1

Max. gear ratio

179.3:1

Efficiency

84–98%

Friction

Rolling

Heat generation

+++

Lifetime

+++

Noise level

+++

Price

€€€€

Producer, manufacturer and supplier of right angle gear motors

Strong and sturdy right angle gear motors for top performance and optimal axial and radial load capacity.

STEEL-IT coating

BEGE combines expertise in drive technology with specific industry knowledge. Especially for companies in the food industry, our right angle gear units are available on request with an industrial STEEL-IT coating for optimal protection and food safety.

This STEEL-IT coating has been specially developed in accordance with HACCP requirements for the processing of materials in contact with food. The manufacturer is the market leader in corrosion-resistant and durable coatings.

Longer life thanks to coatings that protect against wear, heat, moisture, corrosion and chemicals.

Read more about STEEL-IT coatings.

Stainless steel right angle gear motors

For machine builders in the agrifood industry who prefer stainless steel right angle drives, BEGE produces stainless steel right angle gear units and gear motors. This stainless steel product line excels in power, efficiency and food safety, and is characterized by high-quality materials, hygienic design and food-grade quality.

We co-create advanced drives without compromising on quality, reliability and performance. Our food-safe stainless steel gear units and gear motors are often installed in systems where extremely high humidity levels and frequent cleaning cycles occur.

Choose durable and food-safe stainless steel right angle gear motors if you need to comply with the strictest international quality and hygiene standards.

Read more about durable food-safe drives.

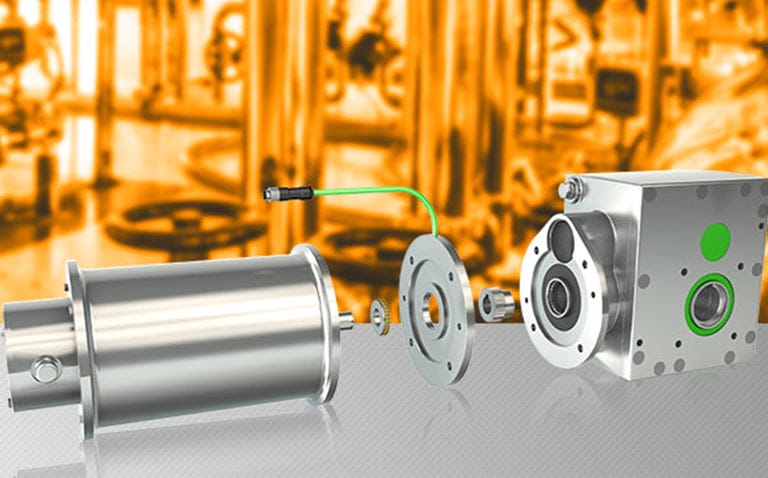

BEGE right angle gear units and gear motors

For machine builders who use right angle transmissions in their machines, we offer a wide range of high quality right angle drives.

Co-engineering

We know the specific challenges faced by machine builders in various industries and the importance of machines that stand out for their high quality, efficiency and great performance.

We are one of the few suppliers on the market that works closely with our customers’ professionals. In co-engineering, we work together to deliver an integrated drive and control solution within the specified objectives and schedule. We strive for close cooperation on an equal basis with the machine builder or end-customer.

Our engineers have many years of experience in designing and engineering custom solutions for drive and control issues.

Comprehensive solution

As a knowledge partner, we assist machine builders in automating their drive and control processes. We combine expertise in drive technology with specific industry knowledge.

The result is a fully integrated, customer-specific drive system that increases the competitive advantage of our customers’ production facilities

We also manufacture high-quality drive components, so we are able to deliver from stock quickly. Our extensive product portfolio is invaluable in this respect. All components are assembled and tested in our own assembly department and finished in our paint shop to produce a high quality drive.

Would you like to know how our right angle gear units and gear motors can help your business?

Arrange an appointment with our engineers.