Hypoid - BPM

High Quality Products

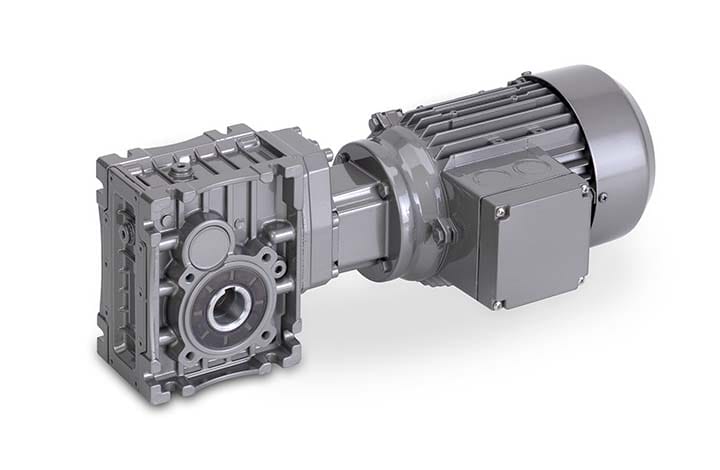

BEGE BPM Serie – Hypoid Gear Motors

Lightweight and high efficiency. BEGE aluminum hypoid gear motors are often used for dynamic applications with large gear ratios and small installation space. Hardened and ground Gleason spiral teeth ensure a very high torque range.

With the BPM series of hypoid gear motors you achieve maximum efficiency by using mainly rolling friction (efficient bevel gear motor) instead of sliding friction (worm gearbox).

Hypoid Gear Motors: features & benefits

Technical specifications & more info

Technical specifications

| Ratio | 7,5:1 - 300:1 |

| Output speed (rpm) | 4,5 - 187 |

| Nominal torque (Nm) | 6 - 584 |

| Max. torque (Nm) | 500 |

| Motor | 3-phase IEC AC-Motor |

| Power range (kW) | 0,12 - 4 |

| Voltage/frequency | 230 / 400V - 50Hz 400 / 690V - 50Hz |

| Efficiency class | IE3 (≥0,75kW - 2 / 4 / 6-poles) |

| Protection class | Standard IP55 max. IP66 |

| Isolation class | F |

| Material | Aluminium |

| Lubrication | ISO VG320 synthetic oil |

| Lifetime (L10h) | > 15.000 |

| Certificates | CE, UL/CSA, ATEX |

Variations

| IEC Motor size | IEC63 - 112 |

| Mounting executions | Foot-mounted Flange-mounted |

| Shaft configuration | Hollow output shaft Single output shaft Double output shaft |

| Output shaft diameter (mm) | 20 - 40 |

| Coating / color | According to ISO 12944 RAL7031 |

Optional features

MIG encoder

PTC thermistor

Bimetal temperature switch

Brake-motors

Pole-changing-motors

ATEX-motors

DC-motors

Special voltage / frequency

Increased protection

Reinforced output shaft bearing

Stainless steel output shaft(s)

Installation and removal elements

Shrink disc

Torque arm

Hollow shaft cover

Forced ventilation

Repair & Maintenance

Is a current component or drive system in need of maintenance or repair? BEGE has extensive knowledge of a wide variety of drives and systems. We guarantee a rapid resumption of operational procedures.

Your Reliable Partner in Drive Solutions

We make life easier for industrial enterprises by creating, optimizing and maintaining high-quality drives.