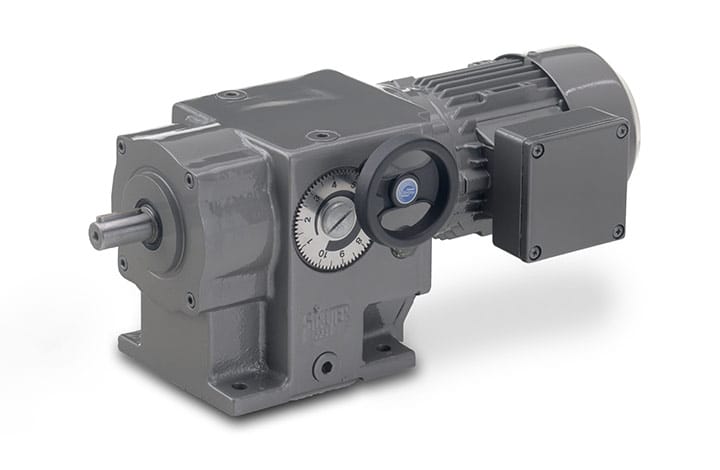

Variable speed gear motors

Robust, durable and cost-efficient variable speed gear motors. In standard versions and available with many options.

Variable speed gear motors for direct and robust speed control

Variable speed gear motors offer robust and direct speed control for machine builders and end users. BEGE helical and helical bevel variable speed gear motors are compact and available in 7 different frame sizes.

BEGE is the only manufacturer in the Netherlands, so communication is clear and direct. Our variable speed gear motors have a variable control range of 1:10 and can be adjusted when the machine is in operation or stopped. This prevents production downtime.

Product overview

Electronic transmission control is not always the right solution. It is vulnerable and sensitive to chemicals and moisture. This can lead to a multitude of issues. Mechanical transmission controls are a robust alternative. Variable speed gear motors with hand wheel allow the user to control the drive speed quickly and directly in humid working conditions. There is no need for an electrical controller. In addition, they are usually more cost-efficient in terms of maintenance, service life and ease of use.

We manufacture a wide range:

Custom variable speed gear motors

In addition to our wide range of frame sizes and gear ratios, we also supply custom solutions. This can be useful for new machines with industry-specific requirements.

- Stainless steel output shaft

- Brake motor

- Remote speed indicator (digital or analog)

- Electric remote control

- Forced cooling

For replacements, custom solutions often offer higher reliability, lower cost and easy exchange.

Where necessary, we can use drawings or reverse engineering to create replacement variable speed gear motors for uncommon existing sizes. These gear motors are equipped with an IEC electric motor as standard, making it easy to replace only the motor.

BEGE is clearly ahead of other providers in this respect.

Manufacturer of robust variable speed gear motors

Our robust variable speed gear motors offer direct speed control with optimal reliability even in the toughest working conditions.

BEGE variable speed gear motors

View all products

BEGE variable speed gear motors are robust, durable, cost-efficient and low-maintenance. They come in 7 standard frame sizes and are made according to the customer’s specific requirements with a wide range of options.