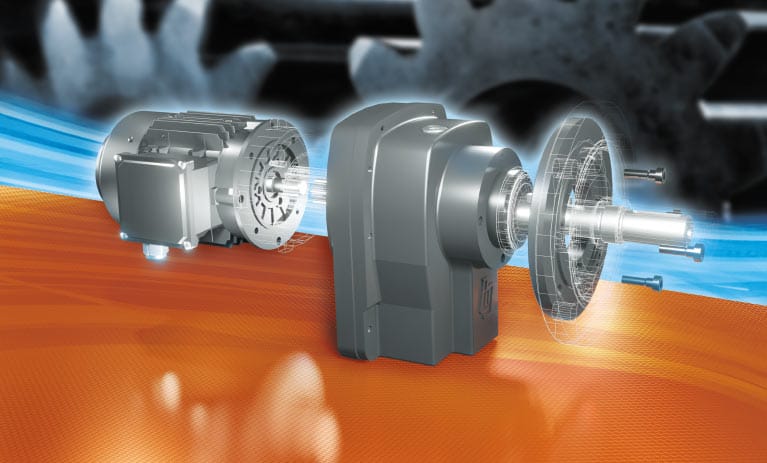

Helical gear motors

BEGE has been producing helical gear motors since the 1980s. Over time, they have evolved into the 3 powerful series that we now supply.

Proven and powerful helical gear motors

BEGE is a manufacturer of coaxial gear motors known for their powerful performance in driving robust machines.

Our helical gear motors are suitable for applications requiring high precision, reliability and torque. They are the ideal choice for many machine builders because they are suitable for a wide range of applications. We have a large stock of gear motors and can deliver very quickly. And because we produce the gear motors ourselves, we are able to customize our products to customer requirements.

Product overview coaxial gear motors

Helical gear motors are essential for the operation of numerous machines and installations. At BEGE, we understand the importance of this drive component, which is why we produce 3 different series with high torques and optimum efficiency.

Customer-specific helical gear motors

BEGE produces customer-specific gear motors that perfectly meet the customer’s requirements and wishes.

- Adapted gear ratio and torque capacity

- Shaft configurations: different shaft lengths, diameters and keyway sizes. Possible even with one-off quantity

- Mounting configurations: foot, flange or foot-flange

- Electrical specifications: different voltage, frequency and/or higher insulation class

- Motor type: AC motor, DC motor, ATEX, pole-changing or single-phase motor

- Modified protection (max. IP 66) against environmental factors such as dust, moisture and extreme temperatures

- Finish: corrosion-resistant coating (type and environmental class C1, C2 up to and including C5-M)

- Accessories and sensors: brakes, forced cooling, encoders, temperature sensors, vibration sensors, motor protection switches, etc.

Your reliable partner in drive solutions

We make life easier for industrial enterprises by creating, optimizing and maintaining high-quality drives.

Helical gear motors at BEGE

View all helical gear motors

BEGE helical gear motors have high torque density, a wide range of gear ratios and are available in many versions. Custom-made modifications are also possible.