Corrosion protection

Maximum corrosion protection for drives. Our high-quality coatings and stainless steel drives ensure a longer lifespan and increase reliability.

Ways to prevent corrosion

BEGE understands corrosion’s complexity and the technical challenges it presents to machine builders and their customers. General measures to protect against corrosion include choosing the right surface finish, regular visual inspections, careful maintenance, thorough cleaning, and the selection of suitable materials and coating applications.

We ensure effective protection with high-quality anti-corrosion coatings and an extensive range of stainless steel drive components. Our expertise enables improved safety, reliability and productivity of machinery and equipment, as well as optimal performance and longevity. Discover our corrosion protection systems.

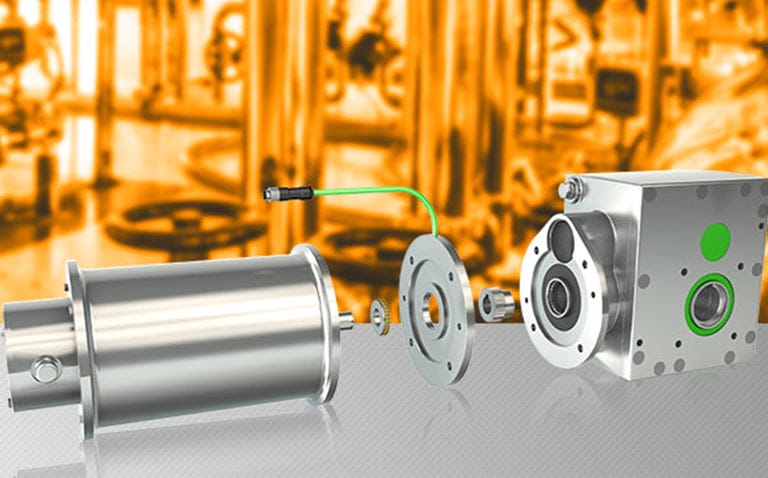

Anti-corrosion coating

Food-grade and corrosion-resistant coatings are used to protect drive components, such as gear units and electric motors, from corrosion and wear.

BEGE uses special C5M coatings that are exceptionally resistant to surface rust, oxidation and corrosive factors in the environment, such as mineral oil, lubricants, emulsions and solvents. We also offer STEEL-IT coatings that are specifically designed for food processing equipment. These provide durable protection against corrosion while also meeting stringent hygiene standards.

Both coatings are ideal for wet and corrosive applications, where they can help extend the drives’ lifespan and reliability.

Benefits of coatings:

- Protect against rust and oxidation and safeguard the integrity of the metal.

- Withstand harsh industrial environments, including those characterized by extreme temperature and chemical exposure.

- Reduce maintenance frequency and lower operating costs.

- Save on the cost of materials by making cheaper base metals corrosion resistant.

- Customized to provide optimum protection against specific chemicals or extreme conditions.

- Offer aesthetic variety with coatings in different colors and finishes.

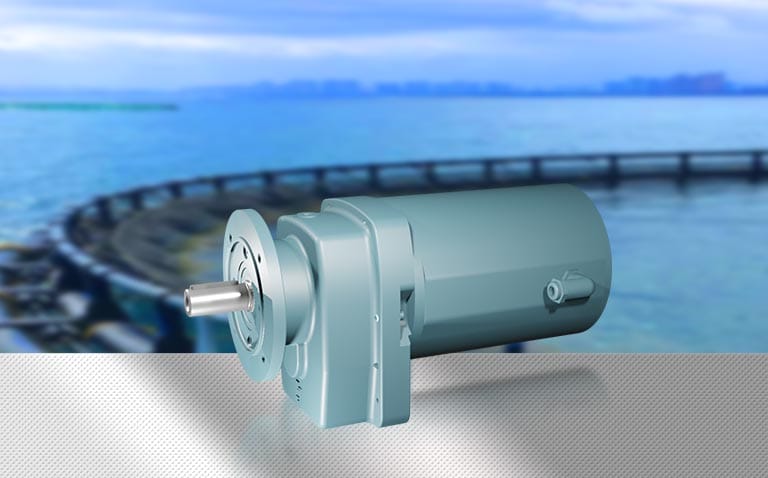

Stainless steel drives

Stainless steel drives are critical in applications where hygiene and durability are top priorities.

BEGE supplies drives that benefit from the corrosion-resistant properties of the high-quality materials used in their manufacture, such as AISI 316, giving them excellent resistance to the destructive effects of moisture, salt and chemicals. This makes our stainless steel drives ideal for use in both the food processing industry and in marine and chemical processing facilities. The smooth finish and rugged design of these drives minimize dirt adhesion and facilitate cleaning, essential for compliance with stringent hygiene standards.

While stainless steel may appear to be the more expensive option at first, the long-term savings on maintenance costs and extended longevity more than compensate for the initial investment. This makes stainless steel drives an economically sound choice for businesses that value durability and reliability.

Benefits of stainless steel drives:

- Prevent corrosion, including under extreme conditions.

- Require less maintenance due to natural corrosion resistance.

- Increase operational reliability of machinery and equipment.

- Facilitate hygiene due to ease of cleaning and ability to withstand high-pressure cleaning.

- Resistant to high temperatures and chemical exposure.

- Lower total cost of ownership over the long term.

The best anti-corrosion solution: stainless steel or coating?

There are a number of factors to consider when deciding whether to opt for a stainless steel drive or a coating for corrosion protection:

- Reliability: if longevity and a high level of reliability are critical, stainless steel is more durable despite the higher initial cost.

- Cost: in some situations a stainless steel drive’s advantages will not weigh up against the cost; in that case, a coating may be more suitable.

- Durability: in extremely harsh industrial environments, stainless steel is often the better choice due to its inherent corrosion resistance.

- Operating conditions: stainless steel is ideal for environments with high chemical exposure, whereas in less corrosive environments a coating may be sufficient.

- Maintenance: stainless steel requires less maintenance than coated surfaces, which need to be re-coated regularly to retain their protection.

- Health: in industries such as food or pharmaceuticals, the non-toxicity of stainless steel makes this option preferable to coatings.

- Application: if the factors above do not apply, then the specific application will determine the choice between stainless steel or a coating. Our experts are happy to support you in your decision-making process.

Want to know more about how BEGE can help your business? Looking for a custom, corrosion-resistant drive? Arrange an appointment with our engineers.

High-quality stainless steel drive components

Discover our extensive range of stainless steel drive components with ultra-hygienic properties. Ideal for industries with demanding corrosion resistance requirements.

Want to extend the lifespan of your equipment? Improve your hygiene standards? Minimize downtime? Call our engineers to discover the best corrosion-resistant custom drive solution for you.

More from BEGE on corrosion protection in drive systems

Read more about corrosion-resistant drive components and systems in these curated articles, and discover how BEGE supports machine builders across various sectors with corrosion-resistant drive solutions.

Want to know more about how BEGE can help your business? Looking for a custom, corrosion-resistant drive? Arrange an appointment with our engineers.