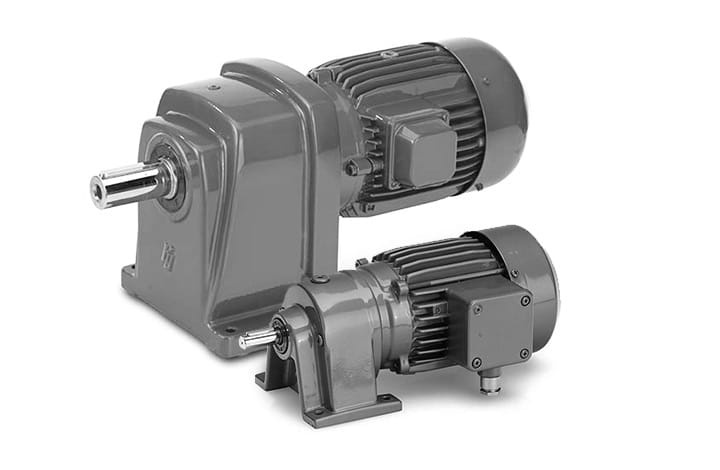

Gear motors

High-quality BEGE gear motors drive machines with power and efficiency. Standard versions and custom options. View our wide range of products.

Gear motors

BEGE is a leading manufacturer and supplier of gear motors, known for their powerful performance and reliability in various industries and applications. We offer not only powerful standard products, but also custom solutions to meet our customers’ specific needs. At BEGE, we fully understand and recognize the vital role gear motors play in the operation of numerous machines and installations. That’s why we offer eight different categories to meet different requirements.

Product overview gear motors

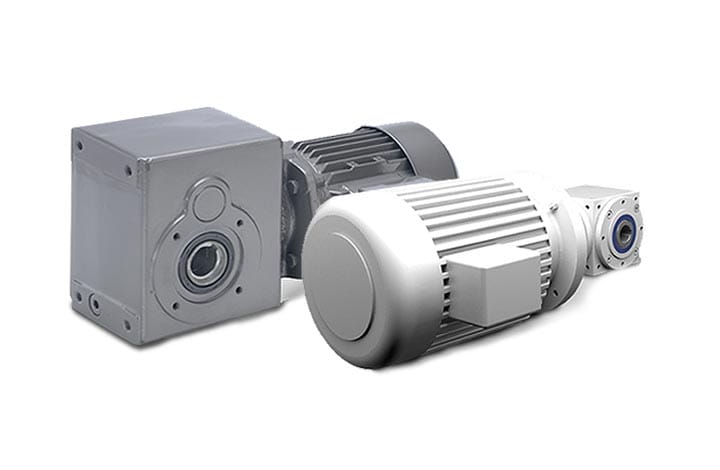

Our range consists of several categories: helical, stainless steel, parallel shaft, hypoid, bevel gear, helical bevel gear and worm gear motors. We also offer various designs, options and customization. We are happy to assist you in finding the right gear motor for your needs.

Gear motors for high-power transmissions

What is a gear motor?

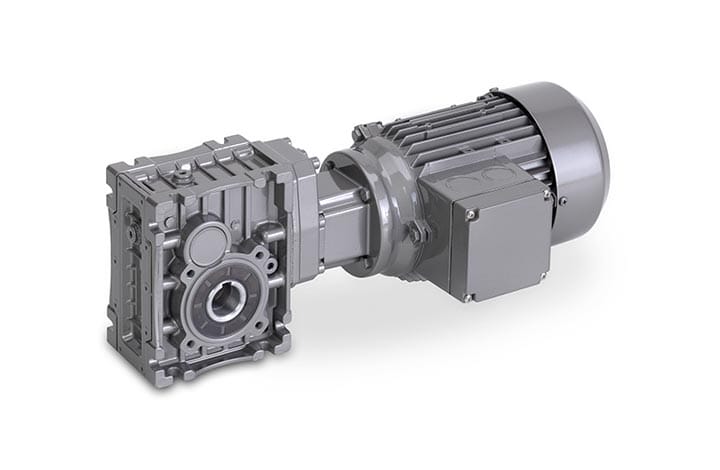

A gear motor is an ingenious combination of a gearbox and an integrated electric motor, which allows the power and speed to be precisely adjusted to the requirements.

At BEGE, we combine the electric motor with a bevel gear, helical bevel gear, worm gear, parallel or parallel shaft mounted gearbox.

How do we do this?

A critical part of a gear motor is the gearbox with its gears. These gears transfer the motor power from the input shaft to the output shaft, resulting in a reduction of the rotational speed and an increase in torque. The design of the gearbox determines its suitability for different loads and operating times, whether light, medium or heavy.

The advantages of a gear motor

- Adjustable power and speed

- Higher torque for heavy loads

- Space saving thanks to compact design

- Efficient energy transfer

- Accurate control, critical to precision

- Durable for reliable and long-lasting use

- Flexible, adaptable to needs

- Versatile, suitable for various environments

- Cost-saving and extended machine life

Your reliable drive partner

We make life easier for industrial companies by creating, optimizing and maintaining high-quality drive systems.

Gear motors at BEGE

View all gear motors

BEGE gear motors are powerful and efficient. Available in a wide range of designs. Customer-specific custom options are also possible.